So, I get bored of the math, I start doing some actual chassis modeling, and I happen upon the classic "where the fuck am I putting the shock" conundrum.

And then, I have what can only be described as a total existential catastrophe. What kind of bike do I really want this to be? Why am I building it? Why do I ride motorcycles at all? Why is everything so goddamn complicated always?

Let's back up a bit, and see if I can explain without being dizzingly circular.

Springs

Springs hold up the meat of your motorcycle (and you, you goddamn meatsack). The wheels and suspension bits sit on the tires, but the "suspended mass" is supported by the spring forces. What you end up with is two spring-mass systems (front and rear) that react to bumps, dips, and cornering forces.

How hard the spring actually pushes down on the suspension (using the contact patch of the tire as a consistent reference point) is called the wheel rate.

Mostly, springs don't push directly on the wheel, they act through suspension (in a telescopic fork they do basically act directly on the wheel, but that's boring and stupid). Because you can play all sorts of games with leverages and links, you can make the spring's effect on the suspension change as the suspension moves - make it progressive (increasing) digressive (decreasing) or linear (constant).

When you mount a shock directly between swingarm and frame, you basically only have "linear" as an option. Yes, the shock swings slightly, so you can make it a bit progressive or digressive, but basically it's just a lever, and levers don't really change shape. It's simple, it's elegant, it's lightweight. ALL THINGS I REALLY WANTED FOR THIS BIKE. Less bearings, less parts, less math, less fabricating, less bullshit. Oh god how I wanted to make a direct-mount shock work. I want to get on something bare-bones and rip across the country, eating squids on sportbikes and basking in the glory of one less bolt to vibrate loose.

So then, you ask yourself, why do all sportbikes (the bikes designed by the industry's tightest-sphincter weight nazis), spend all those precious kilograms on linkages? Marketing? Keeping the bike from bottoming out when Rufus BigBones is riding pillion with his girlfriend on her bike? Below is L3na (my Gixxer, left) and a direct-mount shock comparison. Same spring rate, same shock stroke, same wheel travel, same sag setting.

The wheel rates of the two designs are plotted below. Note how the vertical scales aren't the same, but I've added some numerical tags to help the comparison

Springs store energy. Size X spring = size X energy bucket. Suspension linkages don't perform any magic - the bump that would bottom out the direct-link would also bottom out the progressive link, above. Linkages change when that energy is stored.

The black line in the plots above is static sag - where the suspension would sit in a straight line while coasting. If you notice, L3na's wheel rate is 28.3N/mm, where the direct-link is 30.7. That means every bump feels 11% harsher on the direct link.

Next, look at 60mm wheel displacement - both bikes have a 31.1N/mm rate. Here, mid-corner (where the cornering forces compress the suspension) a bump feels the same on both bikes.

Beyond 60mm, L3na's suspension feels harsher. At 80mm of displacement, L3na is 34.4N/mm to the direct's is 31.8, or another 11%.

The magic here is this: where the rear wheel spends most of its time - between upright and mid-corner - L3na's suspension is softer (being nicer to the rider, and more importantly to the tire) while still being able to handle as big a hit without bottoming as the direct link. Remember - being nicer to the tire means more grip & and less wear, making the bike faster.

The harsher bottom-half of L3na's suspension would only be felt during larger hits when the bike is more upright, which is less important for tire and rider abuse (sorry, Rufus...).

Was this revelation about progressive linkages enough to make me abandon my hankering for direct-link? Nope. Let's continue.

Also, here's the other three suspensions I tried, including that direct-mount job:

To figure out what the ride frequency actually should be required I (again) steal Suzuki's work by reverse-engineering L3na and Suzi. I measured up the links and springs to find the wheel rates, and estimated the rear suspended mass to find ride frequency at different suspension positions.

Also, no. I decided this is going to be the motorcycle I deserve, even if it's not the one I want to build. The matched frequency works for cars, and now my hands are not tied by telescopic forks. I'm going to make the front ride frequency ~90% of the rear. In Hossack we trust, I guess.

I'm going to aim for ~2.3Hz for a ride frequency in the rear. I figure splitting the difference between Suzi and L3na is a good target. Also, my hands are a bit tied by my choice in dampers.

The black line in the plots above is static sag - where the suspension would sit in a straight line while coasting. If you notice, L3na's wheel rate is 28.3N/mm, where the direct-link is 30.7. That means every bump feels 11% harsher on the direct link.

Next, look at 60mm wheel displacement - both bikes have a 31.1N/mm rate. Here, mid-corner (where the cornering forces compress the suspension) a bump feels the same on both bikes.

Beyond 60mm, L3na's suspension feels harsher. At 80mm of displacement, L3na is 34.4N/mm to the direct's is 31.8, or another 11%.

The magic here is this: where the rear wheel spends most of its time - between upright and mid-corner - L3na's suspension is softer (being nicer to the rider, and more importantly to the tire) while still being able to handle as big a hit without bottoming as the direct link. Remember - being nicer to the tire means more grip & and less wear, making the bike faster.

The harsher bottom-half of L3na's suspension would only be felt during larger hits when the bike is more upright, which is less important for tire and rider abuse (sorry, Rufus...).

Was this revelation about progressive linkages enough to make me abandon my hankering for direct-link? Nope. Let's continue.

Every mass bouncing on a spring has a natural frequency, where the duo will bounce at a certain rate. Stiffer the spring/lighter the mass, the faster the rate. When applied to vehicles, this is called ride frequency. Using ride frequency is a simple way to describe how stiff the suspension feels (from the springs, anyway - damper settings also change the hard/squishy feeling, but damper settings are the cart behind the spring's horse). Ride frequency is just a simple math tool that lets you ignore how much the bike actually weighs or what the spring rates actually are, and just focus on how they act. Ride frequency is also an easy way to look at how the two ends of the bike behave relative to each other.

The concept of ride frequency/suspension frequency is easy to google - and there's tons of information on what different frequency ranges work for different types of cars. Unshockingly, fucking nothing about bikes. One thing that is often talked about is the ride frequency difference front and rear - how you usually want the rear frequency to be higher (you want the rear to bounce faster) so that (making the naive assumption that the vehicle is moving forward...) by the time the dampers have stopped a bounce, the front and rear of the vehicle are bouncing in unison. This makes the vehicle feel planted, especially in corners.

So that ^ ended up being the key to my crisis, but we'll get to that.

How to fix this? Make the rear progressive, too. If the front and rear wheel rates increase at the same time, both ride frequencies rise in unison, so the bump response stays the same.

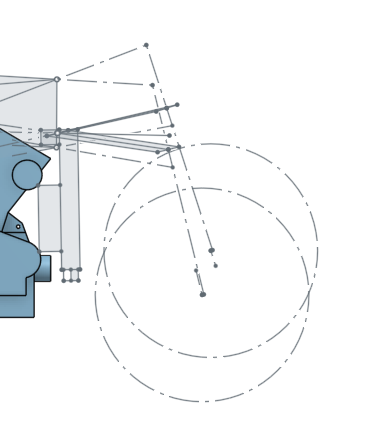

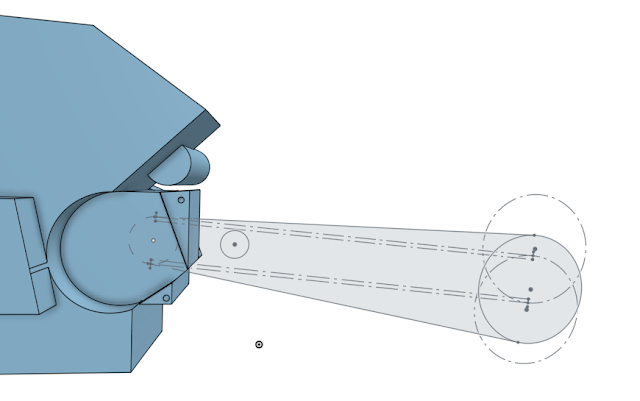

Turns out, I can use the stock "dogbone" pullrod from a GSXR-600 with a different setup that gives me good curves, decent packaging, and a lightweight link:

So that ^ ended up being the key to my crisis, but we'll get to that.

I need to make the front and rear ride frequencies match each other. Seems simple enough - just pick the correct springs.

Oh crap, it's not just springs. Ride frequency comes from wheel rate, not spring rate. Well, I know the wheel rate on a telescopic fork is constant, but what happens on my sweet Hossack front end? Here's that wheel rate plot:

Ugh, damnit. It's progressive. If I match a direct-link rear with mid-corner Hossack front, the bike might suck at low lean angles. If I match it with upright Hossack, the bike might suck at high lean angles.

How to fix this? Make the rear progressive, too. If the front and rear wheel rates increase at the same time, both ride frequencies rise in unison, so the bump response stays the same.

Turns out, I can use the stock "dogbone" pullrod from a GSXR-600 with a different setup that gives me good curves, decent packaging, and a lightweight link:

Also, here's the other three suspensions I tried, including that direct-mount job:

Looks like I have to make the rear a link suspension. Well, there goes 3 bearings, 4 bolts, 10 hours of fabrication, and 2kg. Nuts.

To figure out what the ride frequency actually should be required I (again) steal Suzuki's work by reverse-engineering L3na and Suzi. I measured up the links and springs to find the wheel rates, and estimated the rear suspended mass to find ride frequency at different suspension positions.

Rear:

Suzi, My GS500 = 2.1Hz @ 0* lean

L3na, My GSX-R600 = 2.6Hz @ 0* lean

Front:Suzi = 0.7Hz

L3na = 0.7Hz

So...what gives? Why are the front ride frequencies sooooooo low? Uh, telescopic forks? As far as I can tell, the springs in the fork are chosen A) so you don't bottom under steady-state braking, and B) so the trail is appropriate mid-corner. Looks like that just requires very low wheel rates. No, I didn't forget to count both the left and right springs in the forks.

Also, now we know regular motorbikes have ride frequency differences front-to-rear that are totally out to lunch! I can abandon my progressive link and do whatever I want!

Also, no. I decided this is going to be the motorcycle I deserve, even if it's not the one I want to build. The matched frequency works for cars, and now my hands are not tied by telescopic forks. I'm going to make the front ride frequency ~90% of the rear. In Hossack we trust, I guess.

I'm going to aim for ~2.3Hz for a ride frequency in the rear. I figure splitting the difference between Suzi and L3na is a good target. Also, my hands are a bit tied by my choice in dampers.

Dampers

I'm using stock '11-'20 GSX-R600 dampers. Why? Because I already had one handy (L3na got K-tech for her birthday this year) and because they are about the right spec for the mathbike.

Damping, generally, is matched to the spring rate and ride frequency of the motorcycle in question. If I choose similar springs and ride frequency (meaning similar suspension travel as well) to the GSXR, the dampers should work. They are somewhat adjustable, and I've found the stock GSXR damping pretty livable on the street. I found a company that has a pretty wide range of springs for the shock, too, so if I get buried by harsh ride I can try to dig myself out with different springs.

But AJ, what about progressive springs + direct mount shock? Doesn't that do what you want it to?

Maybe!

First issue is that there's only one progressive spring for this GSXR shock, an 83-113N/mm unit from EPM. I don't really want to be trapped by a single spring option for something as much of a hack as this mathbike.

Second, the dampers are built for linear springs - no matter how compressed the spring is, one more newton of force will compress the spring the same distance. If the spring "fought" the shock harder at one end of stroke than the other, the shock might be underdamped at full bump and overdamped at full droop. KTM uses direct-mount shocks with progressive springs, but their WP dampers also change damping rate during their travel to match the changing spring rate. Good on you for over-engineering that one, KTM (full disclosure, Eyegore rides KTMs exclusively...)